Our safe rooms are built using the most advanced design concepts and materials available.

The heart of the rooms are the ballistic panels. See specifications below.

Residential Ballistic Fiberglass Panels –

Ballistic fiberglass panels are the most efficient and cost effective method of achieving the highest level ballistic protection in a residential setting.

Fiberglass attains the powerful strength of glass white mitigating its tendency to shatter through use of the same material in an interwoven fiber form. A proprietary formula combines woven-roven fiberglass with specially designed resin to tightly lock multiple layers into place.

Machines precision assemble and cure in a press with heat and pressure to maintain quality and consistency. Panels are frequently tested both in factory and by independent laboratories, such as H.P. White.

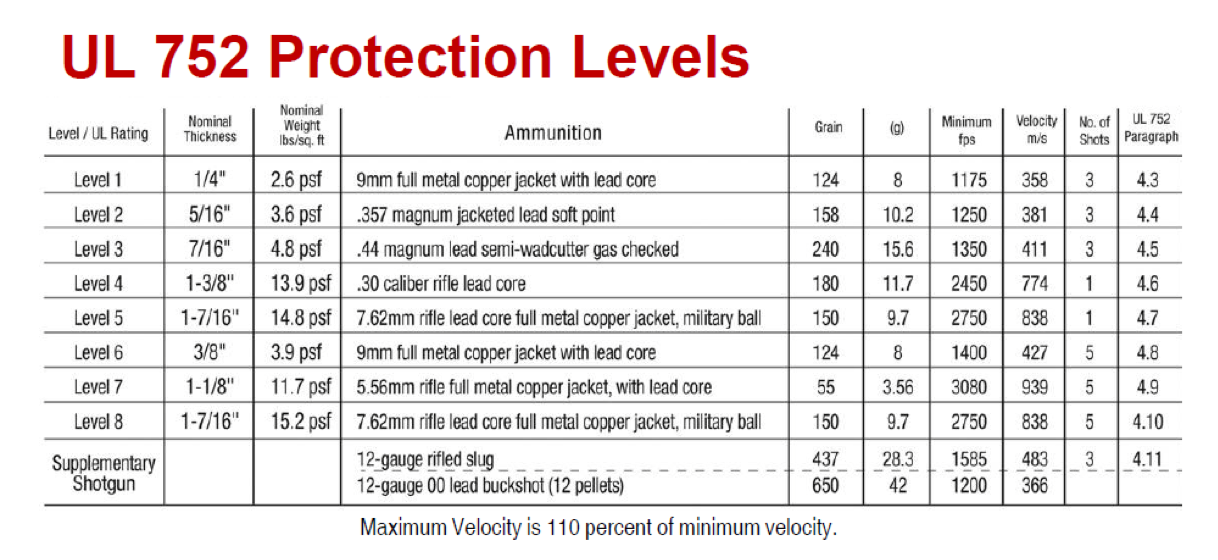

Panels can reach all ballistics levels indicated by Underwriters Laboratory paragraph 752, protecting from everything from 9mm handguns to 7.62 caliber assault weapons.

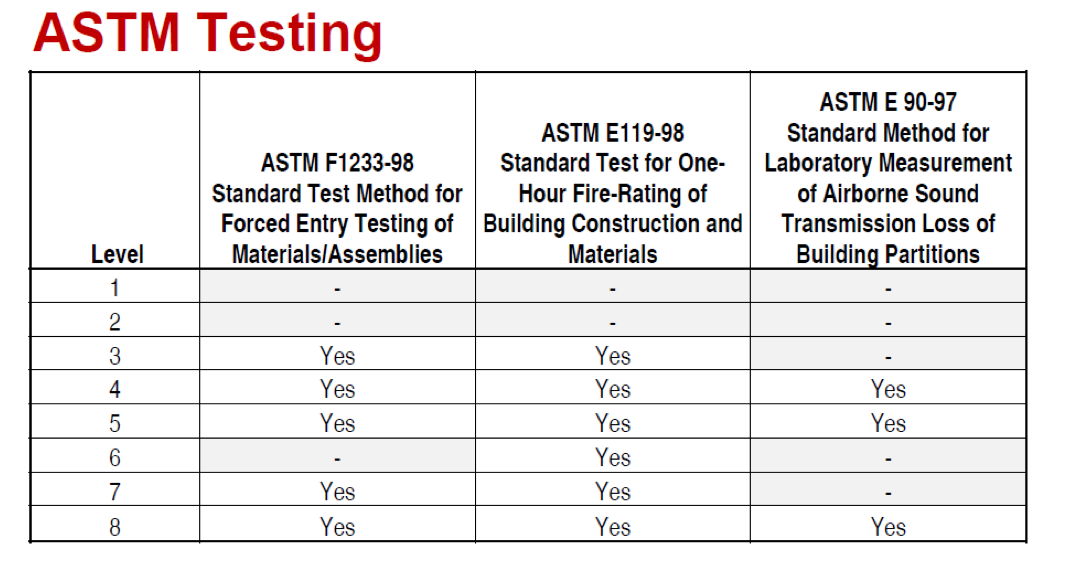

Further, panels reach various ASTM and UL standards for 60-minute fire resistance, forced entry protection, sound insulation and more – making them a dependable solution for a residential application.

Level 8 Fiberglass Bullet Resistant panels are designed to meet the following specification

- Protection of five 7.62 rifle lead core full metal copper jacket, military ball rounds from high powered rifles (e.g. M-14)

- 60 Minute ASTM Fire Standard

- Class IV ASTM F1233 Forced Entry Rating

- No Electrical Conductivity or Signal Interference

Level 8 Dimensions

- The panels you will be receiving are 60” x 108” (W x H) and 36” x 120”

- The panels are 1 7/16” thick

- Each square foot weighs 15.2 lbs.

Installation (additional details on installation document)

Ballistic fiberglass panels can be conveniently installed in walls and behind desks using either polyurethane based glue – such as PL Premium Polyurethane Construction Adhesive – or, more commonly, into wall studs using a self-tapping screw / drywall screw. To ensure protection at seams where two panels meet at a butt joint, a batten strip should be overlaid here. The batten strip should be 4” wide so that each panel is overlapped by 2”. The strip should be offset from wall studs to achieve even thickness.

ASTM F1233-98 Forced Entry Testing Overview

ASTM 60 Minute Fire Resistance Testing Overview

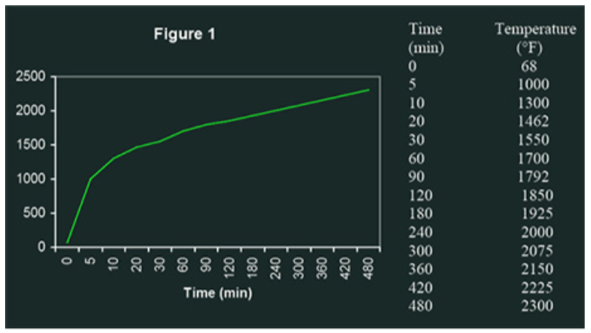

ASTM E119-98 Fire Tests of Building Construction and Materials

ONE-HOUR FIRE RESISTANCE TEST OF A NONBEARING STEEL STUD WALL WITH 1/2″ TYPE X GYPSUM ON THE EXTERIOR AND ½” TYPE X GYPSUM WALLBOARD OVER FIBERGLASS PANEL ON THE INTERIOR

Observations made during the test are as follows:

Time (min : sec) Observation

0:00 Furnace fired at 3:25 p.m.

0:35 Gypsum paper turning dark

0:50 Ignition of the paper

1:10 Paper ash flaking away from

the exposed surface

8:00 Exposed surface turning light

15:00 No visible change

25:00 No visible change

35:00 No visible change

45:00 Light smoke issuing from the top of

the unexposed surface

60:00 Furnace extinguished and assembly moved

into position for the hose stream test

62:15 Hose stream test begins

62:25 Hose stream test ended. All of the gypsum

wallboard was knocked off the exposed surface

and a few of the outer layers of the FRP panel

were hanging from the exposed surface. The hose

stream did not penetrate the entire panel and

did not allow passage of water through the

unexposed layer of gypsum wallboard. Upon closer

inspection, it appear that heat intense

enough to scorch the fabric had penetrated through

the outer five layers (panel comprised of 16 layers).

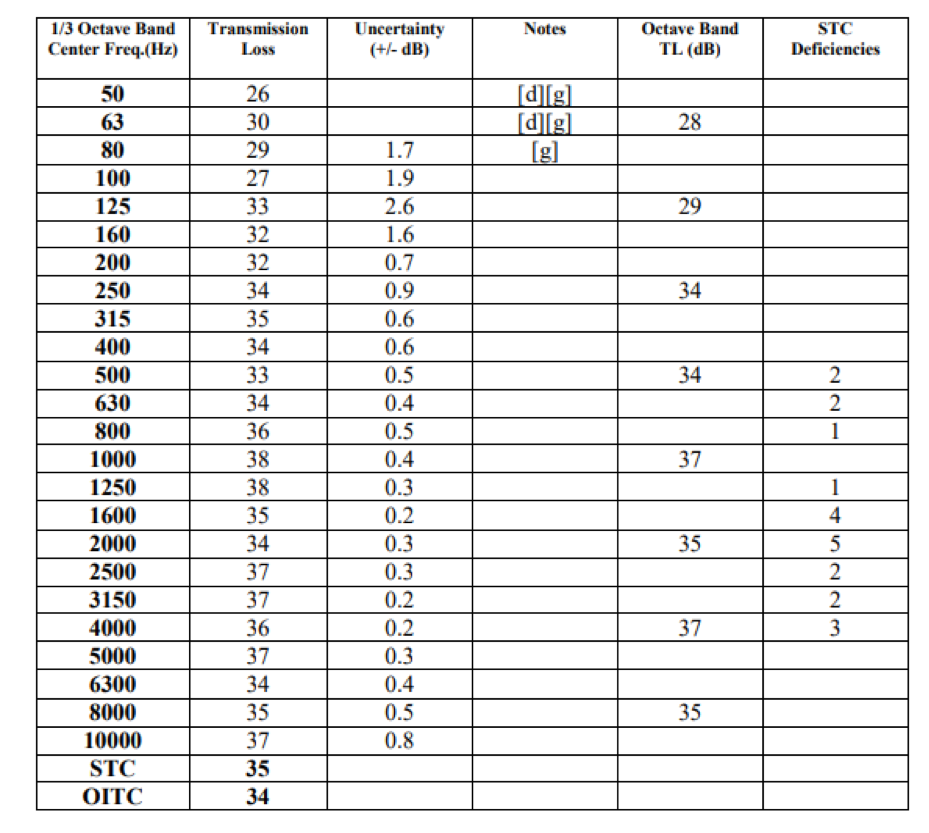

ASTM E90-97 Sound Transmission Overview

Level 4 Bullet Resistant Fiberglass Panels

(Thickness 1-3/8”)

Butt Joined with Batten Strips, Mechanically Attached